|

Sali

guitars enable high dynamic range of playing along

with natural timbre. The tone color, loudness and sustain

are well balanced in all registers. Due to their high

response Sali

guitars

can be

equipped with nylon strings which sound softly, naturally

and convincingly. This is more true also because of

carefully designed directional characteristic of guitar

body, which ensures optimal projection of the sound

towards the auditory.

Sali

guitars are finished with shellac and have

reinforced neck with carbon-fiber strips which prevent

deformations due to humidity and temperature variations.

In year 2014 we started to use truss rods in all our

models.

This enables fast, simple and elegant corrections

of eventual neck deformations. This means that playability of the instrument will not

change during the seasons, as well as over time in

general. The materials used for Sali guitars

are only of first or high quality. This ensures that both life time and

performance of the guitar are something on which you can

rely.

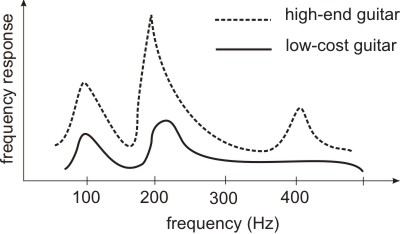

Resonant

frequencies of Sali guitars are engineered

in a way which results in highly consonant (pleasant)

sound. This is achieved by additional trimming of braces

or adding small masses at certain locations on a sound

board during the building process as well as once the

guitar is completed. Sali guitars

are special because

their frequency response is similar to the response

of a high-end guitar from

the simplified picture below.

One can see that the following is true for the resonant

frequencies of a high-end guitar in comparison to a

low-cost guitar:

-

Peaks are

relatively high for good guitars

-

The shape of

peaks is sharper for a good guitar in comparison to a bad

one

-

Peaks form

rather consonant than dissonant intervals (see our

"rule of consonance-dissonance")

(please note, that the

above explanation is stated highly simplified)

Traditional

procedures

Sali guitars are made by traditional procedures which

comprehend the use of hand tools and techniques for wood

working, finishing with shellac, etc. Skilled luthiers in the

past developed techniques for guitar building to the extreme

point and enormous details of their tradition are built

into our

high quality instruments.

We buy wood for our guitars on places with long tradition in

this business.

Our wood is naturally dried for at least 5 years in steady

conditions under our control before we use it in production

process. The quality of

wood is 1st grade or high

grade. We use the following types:

-

spruce or cedar for soundboards

-

mahogany (khaya, sapeli), cedar for necks

-

Indian rosewood or flame maple for backs and sides

-

ebony for fingerboards

-

rosewood for bridges

Handmade

All Sali guitars are hand made.

We spend approximately 150 hours on each instrument.

However it usually lasts 5 months in order to complete one

guitar. This is due to time-demanding finishing with French

polish (if demanded by a customer) and all necessary adjustments of

both saddles, fretboard, etc. once the guitar is finished.

Each instrument is an

unique product, usually made for a known customer. Because one

guitar is treated by only one pair of hands and eyes, we are

able to control all phases of work. Our approach ensures

quality and we trade this quality for your security with

pleasure.

Precision

Precision of guitar making does not affect only its appearance

but also its sound. We are carefully focused into perfect matching

between different parts. This enables thin layers of glue, thus your

Sali guitar will vibrate without any unnecessary loses

of sound.

Very important part of a guitar is its neck with fingerboard.

Sali

guitar has a reinforced neck which prevents

undesirable deformations due to string tension on one side,

and humidity and temperature changes on another side. The neck

reinforcement is performed with carbon-fiber strips which are

extremely light and strong, thus your Sali guitar will

be a joy in your hands. A two-way truss rod enables quick and accurate

neck adjustment if necessary.

We can achieve so desired low string action at all

frets because the neck relief of Sali guitars is

calculated with engineering precision and worked with

accuracy. Consequently the playability of our guitars is

something which enraptures.

Science behind Sali guitars

Several years of different

researches performed at Faculty of

Mechanical Engineering in Ljubljana and later in Samo Sali's

workshop enable that Sali guitars are well balanced

combination of tradition, hand making, precision and

science.

The influence of

machining process on the acoustic properties of guitar

The wood tissue in any tree mainly consists of cells which are

parallel to the tree's stem. These cells are sensitive to

deformations which always occur during hand working or

machining with machine tools of any wooden workpiece. Samo Sali defined the influence of planing,

sanding and milling on the acoustic properties of wooden

resonant boards. In planing the way of cutting the wood cells

is different than in sanding and milling, and consequently

each cutting process affects acoustics of a thin wooden board

in a different way. All these findings are encountered in

process of making Sali guitars.

-

KOPAC

Janez, SALI Samo. The

frequency response of differently machined wooden boards.

J. Sound Vib.,

1999, vol. 227, no. 2., p. 259-269

(PDF, 329 kB)

-

SALI

Samo, KOPAC Janez. The

influence of different machining processes on the acoustic

properties of wooden resonant boards.

CAS j.,

1998, vol. 3, no. 5, series II, p. 15-21

(PDF, 489 kB)

Rule of consonance - dissonance

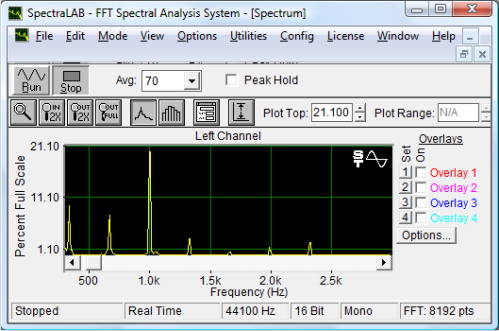

Each guitar tone has its spectrum. A sample spectrum of empty

1st string is shown in figure below. The tone spectrum shows

us which frequencies (i.e., frequency components) are

contained in the plucked tone and how strong they are. There

is certain music theory which says that some combinations of

tones are pleasant (consonant) and another ones are unpleasant

(dissonant) to the human ear. We can apply this

theory for a situation within any guitar tone. Some

combinations of frequency components inside the tone are

consonant and another one are dissonant. In well-sounding

guitars the portion of consonant combinations of frequency

components is large, and portion of dissonant combinations of

frequency components is small in comparison to

low-quality guitars.

Frequency response

of the sound

board

The most important part of a guitar is its sound board. Due to

non-homogeneity of wood, which means that density of wood

tissue varies over the board, the acoustic properties of each

wooden board in nature are different. Each sound board has certain number of wooden reinforcements

(called braces and fans) and we are able to calculate

their locations. Some

places on a sound board are highly inappropriate for gluing the

braces because they can block vibrations. In contrast, some

places are ideal for brace gluing because adding the mass and

stiffness at right locations can increase acoustic response of

the board. Due to already mentioned non-homogeneity of wood

the appropriate and inappropriate places for braces and fans

are different for different sound boards. Adequate measurements and methods for calculation of optimal

position of braces and fans enable beautiful sound of our

guitars. To implement these methods some

braces and fans must be curved with accuracy about 1 mm before

gluing onto the soundboard.

Measurements of

sound board

The luthiers in the past (e.g., Amati, Stradivari, etc.)

developed a method named "tap toning" by which they

established the response characteristics of the board. We

developed an expert system for measuring the response of

guitar sound boards. This system enables us to predict which

frequencies in any tone spectrum of the finished guitar will

be emphasized and which ones will be diminished.

Guitar tone depends much on

sound board

"Tap-toning" method can be

modified in order to produce a high-end quality guitar. Namely,

under certain circumstances we can tap the sound board only at

a specific location although its response will be

characteristic for a whole sound board. In addition, we

found out that tonal characteristics of the guitar can be

correlated with characteristics of certain range of guitar's

frequency response.

Tone improvement

According to the board's response the luthiers in the past

performed additional removing of wood at certain locations to

achieve optimal response which means loud and pleasant sound.

Sometimes it is necessary to perform additional corrections

for a completed guitar as well. If so, we rely on a method

which enables these corrections by removing the wood through the sound hole.

Pictorial overview of

making guitars |